This ambitious challenge has been carried out by a multidisciplinary consortium composed of 4 companies covering the entire value chain of the project:

SOFITEC

DGH GROUP

ONTECH

NoSoloSoftware

The consortium has been supported by AIMEN Centro Tecnológico.

The global trend towards the manufacture of customized, complex products with shorter life cycles is driving the aerospace industry to make changes in the business model. This new manufacturing paradigm poses new challenges, including the implementation of new processes that are integrated as part of a new manufacturing concept. advanced factory, which allows us to approach a model of efficient, agile and flexible manufacturing, adapted to short batch multi-reference manufacturing processes. This approach provides a competitive edge for the company by having a comprehensive solution capable of responding to changing production demands.

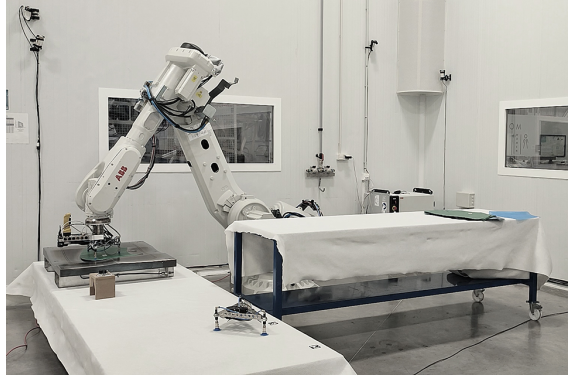

Based on this global need, the PROFETA R&D&I project was born, a new concept of flexible manufacturing in the creation and integration of tools for agile production management (PROFETA).MES), together with the implementation of new highlyrobotic solutions reconfigurable, based on innovative human-centered technologies, enabling more natural and secure human-machine interaction and collaboration.

MAIN RESULTS OF THE PROJECT

The main results achieved at PROFETA include the following technological developments:

– Profilometric scanning using free trajectories.

– Stacking of prepregs in molds.

– Intelligent floor for identification and location of operators in the work area.

– Tracking of people for the security system in work areas through artificial vision and wearable sensors.

– Multi-level security system.

– 3D gesture recognition, for intuitive interaction between manufacturing support systems and operators.

– Manual robot guidance that allows the operator to interact and program the robot in a simple way.

– Management software for reconfigurable production.

– Kitting and manufacturing operations by composite stacking.

The PROFETA project was completed in 2021 and has been implemented in Andalusia and Valladolid, with a total budget of €1.2 million.

Framed in the FEDER Innterconecta 2018 call, it has been subsidized by the CDTI and co-financed by the Ministry of Science and Innovation and FEDER, within the Pluri-regional Operational Program of Spain 2014-2020, with the aim of promoting research, technological development and innovation.