Capability & Experience

Our experience

- New integrated solutions in aerostructures, metal fabrication and composites, repair and aog's.

- Technology, knowledge and attitude. a professional and close service.

- Services based on flexibility, competitiveness and quick response. we support our clients by contributing ideas throughout the entire process.

- Offering the global aerospace market more and better value-added projects.

Our customers

Added value

We developed a complete re-engineering of the products, adding flexibility to the processes and, therefore, to our international competitiveness.

Our concurrent engineering and industrial capacity for manufacturing are the key aspects that allow us to develop precise internal criteria for assembly at the beginning of the value chain, actions that have a positive impact on the reduction of cycle times and costs.

Our added value

Manufacturing

Composites and metallic

Autonomy, efficiency and versatility in the manufacture of any aeronautical element and material in our own facilities.

We develop complete re-engineering on the products, adding flexibility to the processes.

Our added value

Aerostructures

As a process integrator of manufacturing activities, we offer solutions for the assembly of aerostructures and mixed structures made of metallic materials, composites and plastics.

We continue in the evolutionary process of incorporating to our order book, equipped aerostructures of greater size and complexity.

Our added value

Repairs & AOG's

Quick response” repair service anywhere in the world, a wide technological diversity in manufacturing and a complete range of portable equipment, both in composite and metallic materials.

We supply urgent components (aog) and spare parts according to customer requirements in any manufacturing technology.

Our production capacity

This is the way in which we contribute to the technological, organizational and productive evolution of the sector.

Permanently reinvesting in what we consider our pillars, to offer more and better services with high added value.

Automated Painting Facilities

Our production capacity

Metallic

Manufacture of elementary parts and subassemblies in aluminum, steel and titanium.

- Nadcap and 9100 certifications.

5 Axis machining for large elementary parts

AIRBUS, EMBRAER and BOMBARDIER Certifications

Stretch Forming

Sheet metal installations. Hydroforming press and bending technology

Heat Treatments for Metallic Alloys

Complete Automated Surface Treatments BSA/TSA/PSA/CAA/PAA

Our production capacity

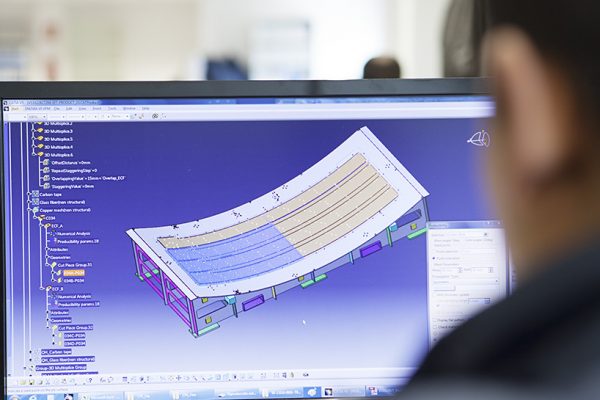

Composites

Manufacture of detailed parts and subassemblies in carbon fiber, glass and aramids.

- Nadcap and 9100 certifications.

CNC robot for cutting and trimming of composite materials

3 CNC machines of 5X and 4X up to 14 m. for cutting and trimming of composites

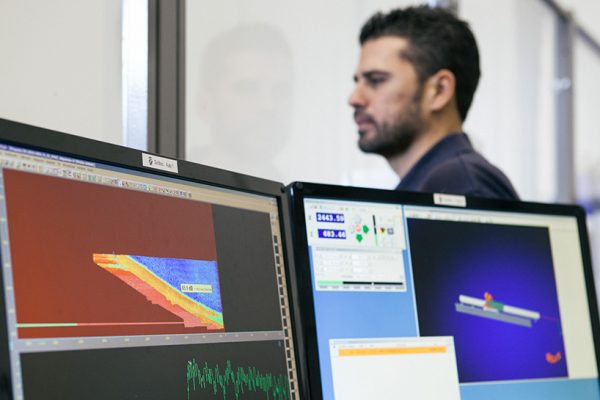

CNC robot up to 14 m. for ultrasonic inspection.

12 and 4 m manual preparation and trimming cabins. respectively.

Our dedicated facilities for assembly operations of aerostructures and assemblies

Metal riveting and fastening

Equipped to perform assembly activities: integration, aerostructures, systems and subassemblies equipping

Our production capacity

Mounting

Integration of aerostructures and equipment units. Design and assembly of manufacturing systems.

- Nadcap and 9100 certifications.

Our dedicated facilities for assembly operations of aerostructures and assemblies

Equipped to perform assembly activities: integration, aerostructures, systems and subassemblies equipping

Metal riveting and fastening

Assembly of subassemblies, whether metallic, composite or mixed.

Painting cabins up to 40 x 16 ft.

AIRBUS, EMBRAER & BOMBARDIER Certifications

Our production capacity

Know-how

The human team that makes up this industrial project represents the most important and crucial pillar for Sofitec.

Master and operational planning. Program management

Purchasing and Supply Chain Management

Manufacturing engineering

Production management

Industrialization. Process engineering

Customer Support